Danish company Unilite, the market-leading manufacturer of quality skylights, has taken a big step towards efficiency and precision in their internal logistics processes. With the Delfi Technologies’ handheld terminal solution, Unilite has optimized goods receipt and dispatch procedures.

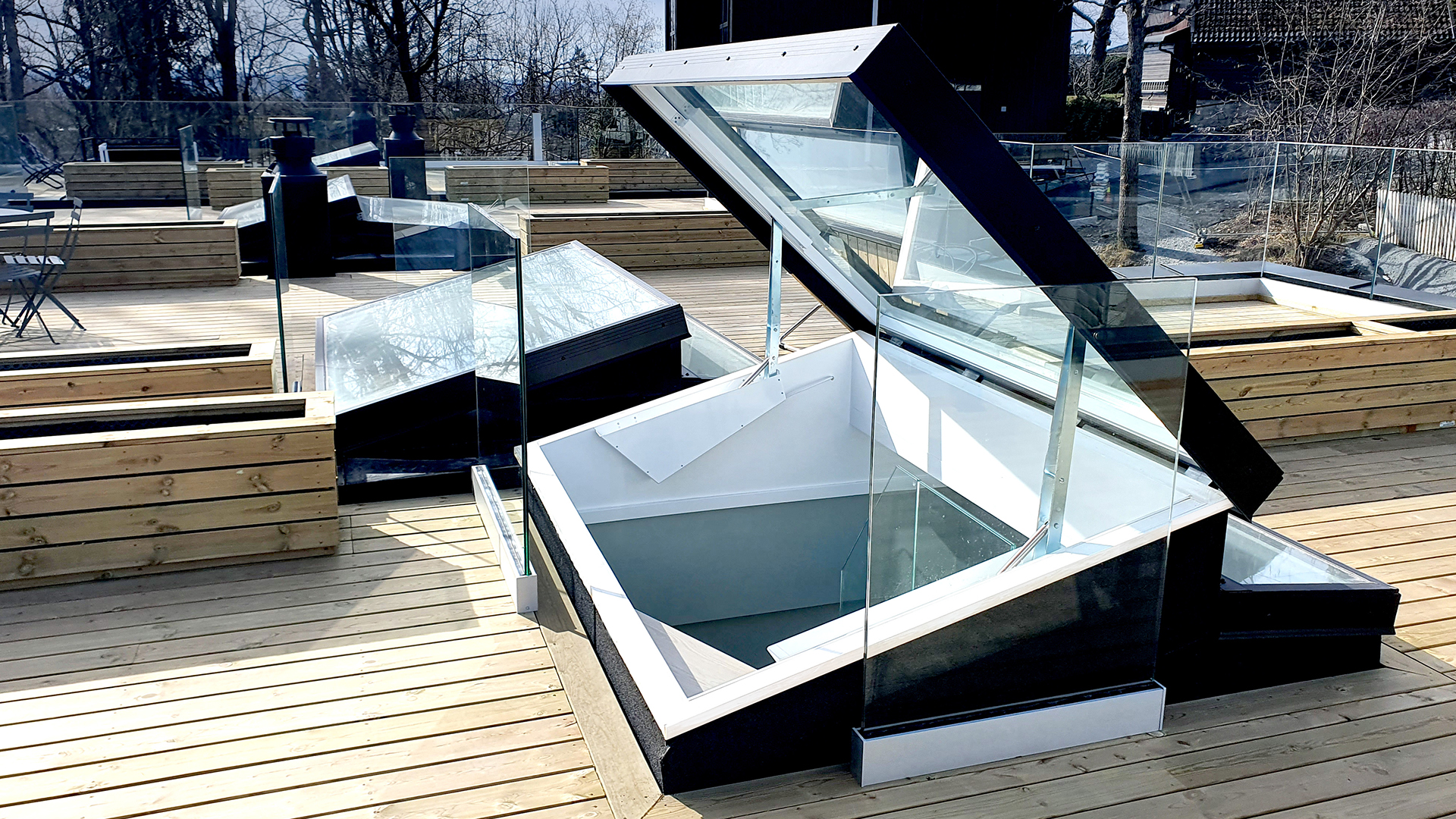

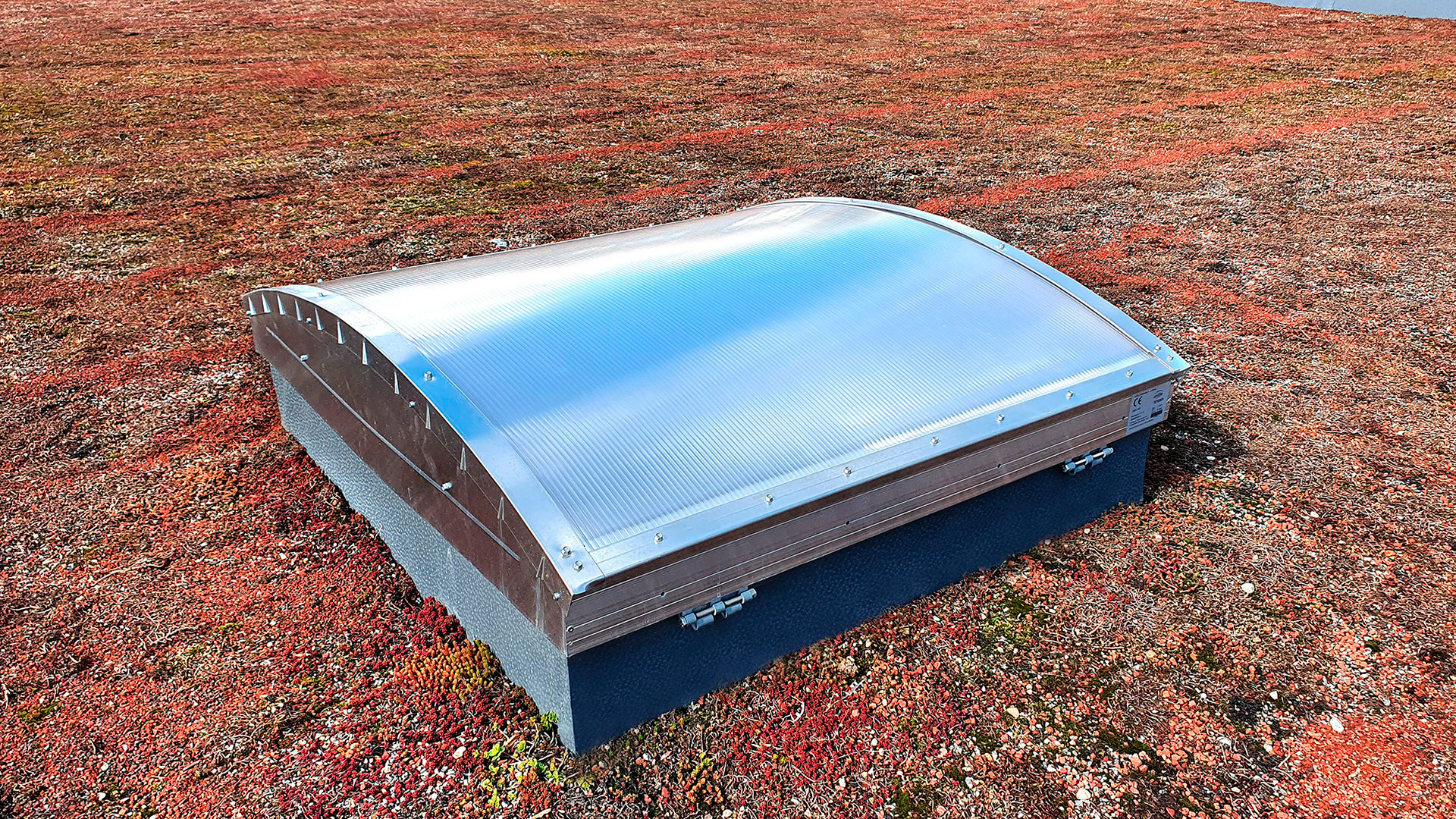

Unilite is known for its premium skylights that meet the increasing demands for insulation, fire safety and air circulation in case of fire. The company’s products are primarily used in large warehouses or office buildings where quality and reliability are particularly crucial.

At Unilite, the value of Danish quality is emphasized, which is why the company has chosen to produce its skylights at its own factory in Snæbum, outside Hobro. With a focus on openness and collaboration, the company delivers skylights, light panels and smoke extraction systems in close dialog with the customer, so the solution is just right for each project.

reduction of errors and faster goods receipt

To improve warehouse and order processes and ensure even higher service quality and delivery reliability, the company has implemented a handheld terminal solution from Delfi Technologies. It’s a warehouse solution with software that automates a number of manual tasks, saving time and eliminating errors.

Previously, Unilite employees had to manually check and record incoming goods using paper-based orders. This was a slow process that was prone to errors and required extra time for administrative work to enter data into the systems. Thanks to the Delfi Technologies’ solution, this process is now automatic, which has led to a reduction in errors and an increase in the speed of the goods receipt process.

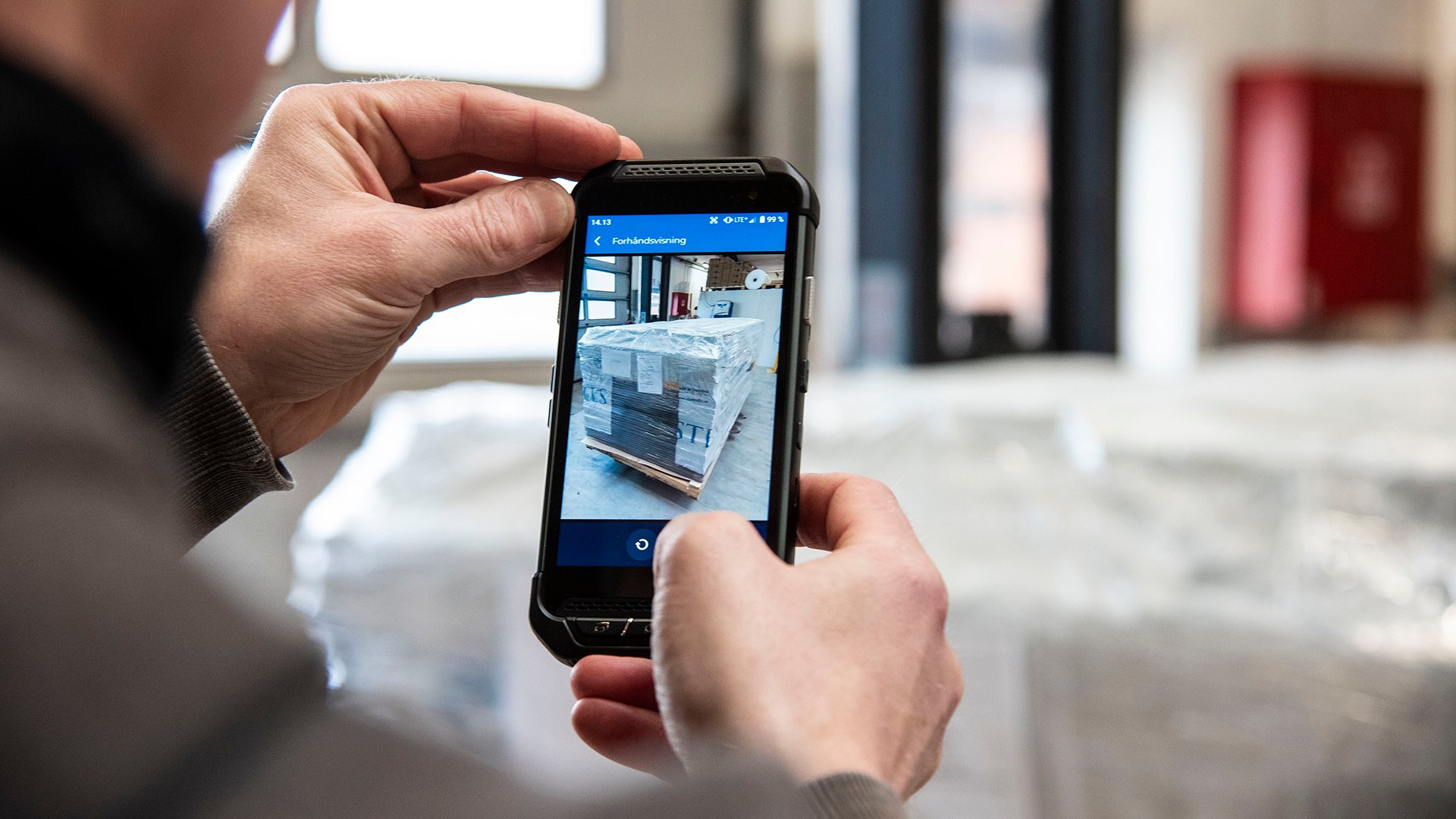

Using the Delfi solution, Unilite staff can easily open purchase orders directly on the handheld terminal and then thoroughly check and scan the received goods. This process ensures an accurate match between order and delivery while minimizing the risk of errors.

documentation improves delivery reliability

Furthermore, the solution improves Unilite’s shipping process by integrating a module that ensures all necessary elements, such as mounting screws and shipping labels, are properly included in each order.

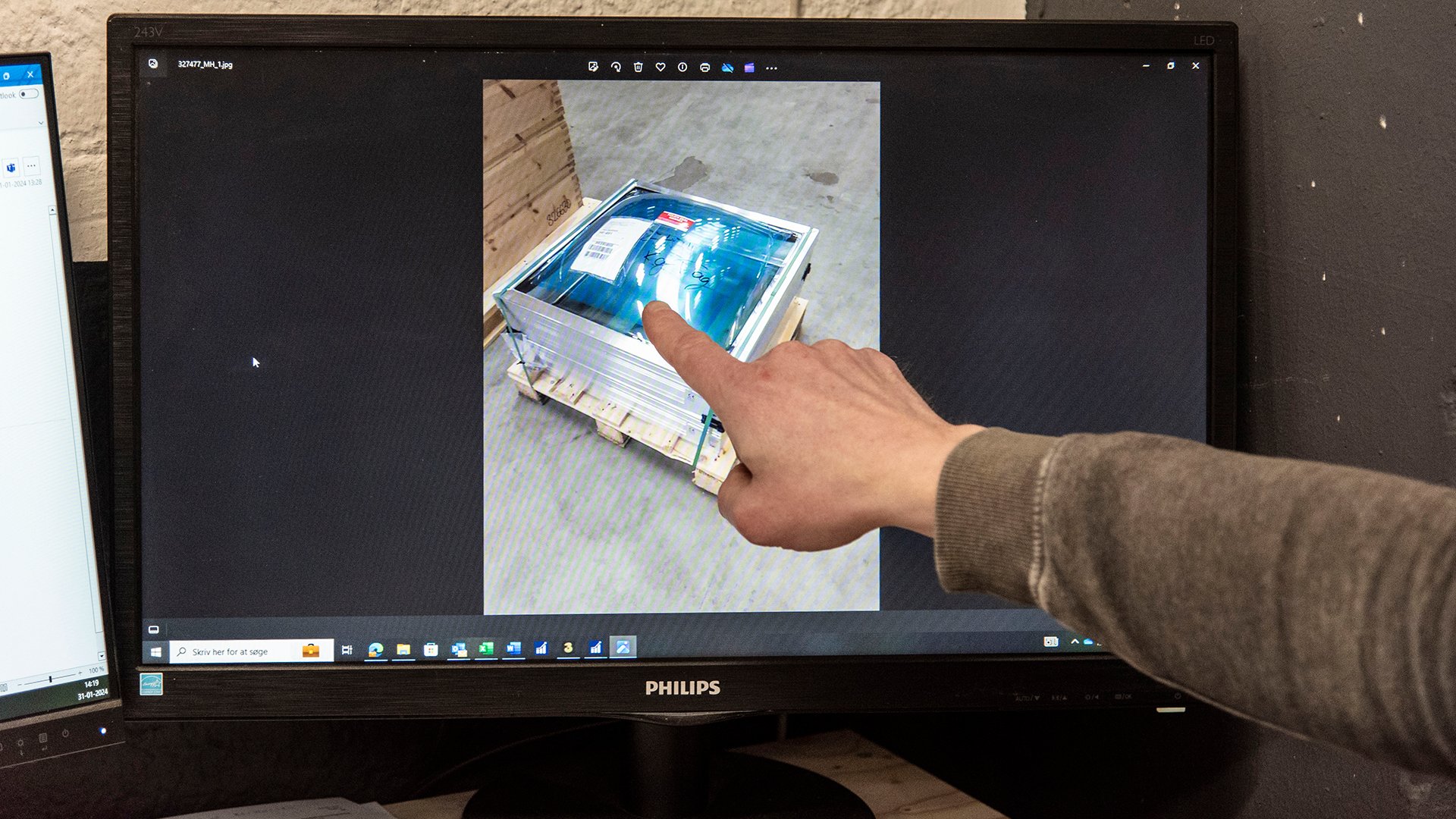

Unilite also has the ability to take pictures of the shipments, making it possible to document the content and condition of the deliveries. This is particularly valuable when shipping to large construction sites where the recipients may not always be present.

Taking pictures of deliveries can improve documentation and delivery security in several ways. Firstly, images provide visual confirmation of what was sent with each order, which can be particularly useful in the event of questions about the content or condition of the delivery. This can help resolve any discrepancies quickly and efficiently.

Furthermore, images can also serve as a useful tool for quality control as they allow the recipient to check the goods before accepting them. If a Unilite customer receives an order and discovers that something is missing, even though it was originally included on the shipping order, it can cause cost and concern. Firstly, missing items can delay the customer’s project, which can result in lost productivity and additional costs. Additionally, the missing item can cast doubt on Unilite’s reliability and quality of service, potentially affecting the customer’s trust in the company in the long run. When Unilite takes an image for documentation, it is automatically uploaded to their Sharepoint and they can access the images directly on the order in Microsoft Business Central.

It is therefore crucial for Unilite to ensure their order processes are error-free to avoid such situations and maintain their reputation as a reliable supplier. Overall, the solution helps to create a more transparent and reliable delivery process, increasing trust and satisfaction for both the company and its customers.

– Delfi Technologies’ handheld terminal solution has been a crucial advantage for the company. We have seen significant improvements in our warehouse and order processes. Previously, there was always some uncertainty about the location and content of our orders, but now we have complete control and documentation. This has strengthened our customer trust and significantly increased our internal efficiency,” says Jan Rysz, Logistics Manager at Unilite.

The next step for Unilite is to implement a location management and order picking module in the handheld terminals. This will further improve their inventory management by providing employees with accurate instructions on where to find items in the warehouse. At the same time, the system will help minimize errors by cross-checking products via barcodes.