LØBESHOP.DK

New solution increases warehouse efficiency at Løbeshop.dk

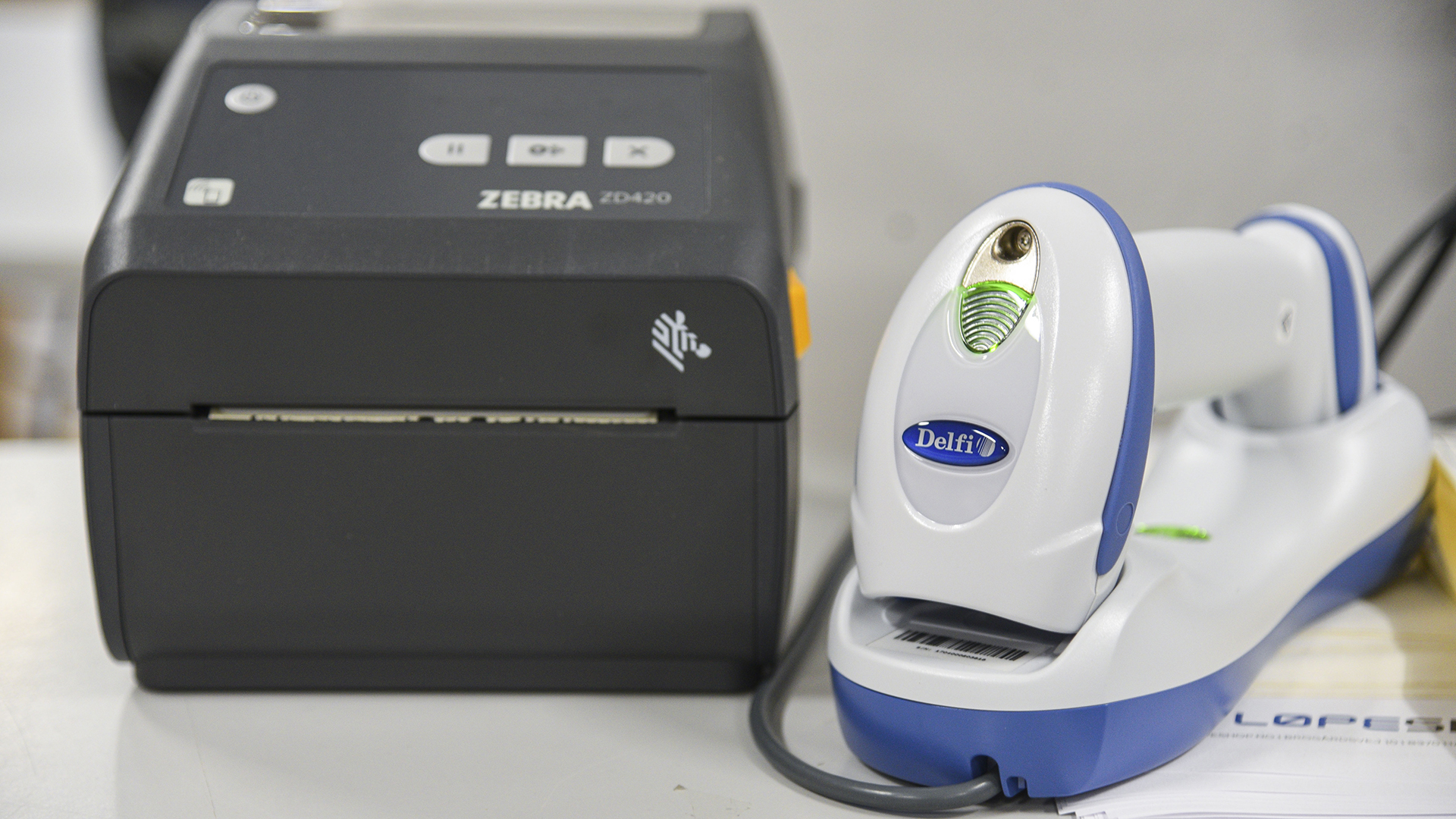

In February 2019, Løbeshop moved into newly renovated premises with more space in the old Trelleborg wheel factory in Hadsten. At the same time, process optimization has been put on the agenda. Among other things, a new scanning system for picking goods has been implemented – and has created greater efficiency in the warehouse.

With Scandinavia’s largest selection of running clothes, running shoes, heart rate monitors, accessories and much more, 140,000 packages are sent from Løbeshop’s warehouse to customers primarily in Denmark, Norway and Sweden every year. The company is experiencing solid growth and has big ambitions to grow further. Most recently, the Netherlands and England have come on the map and have offered an expansion of the webshop. Løbeshop has an ambition to create a strong position in the European market for running equipment.

After a thorough renovation, Løbeshop has moved its office and warehouse into the former wheel factory Trelleborg in Hadsten, just outside Aarhus. However, Løbeshop is only using just over 3000 m2 of the 7000 m2 that the entire building measures. The vacant square meters will be used to establish a community of internet-based businesses, where Løbeshop will offer attractive leases to digital enthusiasts.

"The new scanners are part of our strategy to become even more efficient. When we can optimize processes, we can save time and ultimately deliver parcels faster to our customers. In this way, we can create greater efficiency everywhere."

PROCESS OPTIMIZATION FOR FASTER STOCK PICKING

In connection with the new premises, they also wanted to make optimal use of the extra space. Therefore, process optimization has been put on the agenda as an important focus area, explains Rolf Mørkøre Andersen, who owns Løbeshop.dk together with his two siblings, Sarah Andersen and Jonas Mørkøre Andersen, and their father Ruben Mørkøre Andersen:

– We have a wide network of colleagues in the e-commerce industry and continuously spar when it comes to running a business and optimizing processes. In connection with Black Friday this year, we asked around in the network as we wanted to be able to send parcels more efficiently. We were recommended to implement ring scanners in the warehouse so that warehouse employees can have their hands free while picking goods and handling parcels.

Løbeshop just managed to get the new solution up and running in time for Black Friday, making the shipping process faster and simpler.

DIGITAL TRANSFORMATION TO CREATE GREATER EFFICIENCY

The new solution has opened up opportunities to run a warehouse more efficiently. Today, large parts of the warehouse at Løbeshop are run manually. But the new hand scanning system is part of a transformation in the company, where small and large processes need to be optimized.

– The new scanners are part of our strategy to become even more efficient. When we can optimize processes, we can save time and ultimately deliver parcels faster to our customers. In this way, we can create greater efficiency all the way around,” says Rolf Mørkøre Andersen.

Want to know more?

Contact us today and we'll be happy to get back to you